DR200 Structural

Steel Kit Parts

All

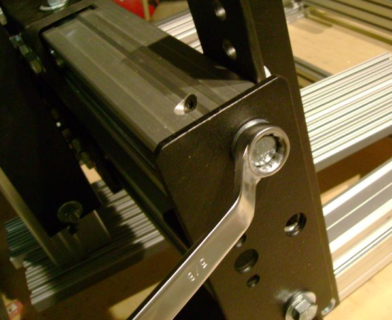

of the steel parts attached to the extrusions are fabricated from

heavy duty 2.5”x2.5”x.25” structural steel angle.

The bearing and extrusion mounting holes are precision CNC fabricated

ensuring easy and accurate machine assembly. Slotted holes are used

in the motor mounts for leadscrew alignment. 1.5”x1.5”x.25”

steel angle braces ensure that, once assembled, the overall structure

cannot shift out of square under machine cutting loads. Multiple

mounting holes on the uprights permit 4 assembly slectable positions of

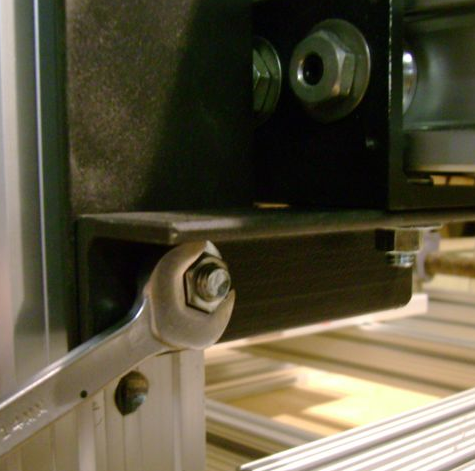

bridge clearance. Just run the

bolts in to the extrusions to assemble the machine.

If any

adjustments are needed simply loosen the nuts slightly, run the

machine back and forth, then re-tighten.

Eccentric mounting bushings

allow precision adjustment of the linear bearings.

Back