CNC

Technology On the Cutting Edge

DigiRout Software

Click on DigiRout Model

Below

There are 3

steps to the software for running the DigiRout CNC router:

Give us a call Toll Free at 866-966-4335 to discuss your CNC Router

application or email us at

sales@digirout .

If you do not currently have a CAD

program then we suggest using Cut2D

which

combines the first two capabilities with one program. Cut2D and Cut3D

can also

interface to most any general CAD program using the DXF file import.

There are 4 steps to cresating the toolpath CAM file:

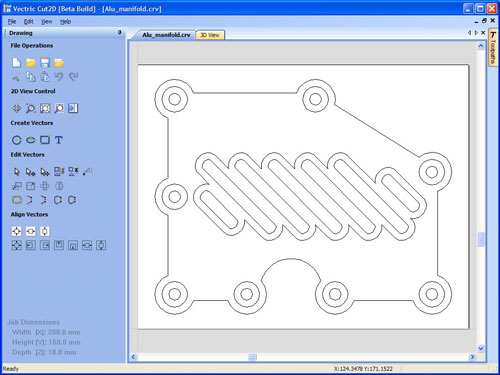

Step 1 - Open a DXF CAD drawing / Graphic design or draw your own projects

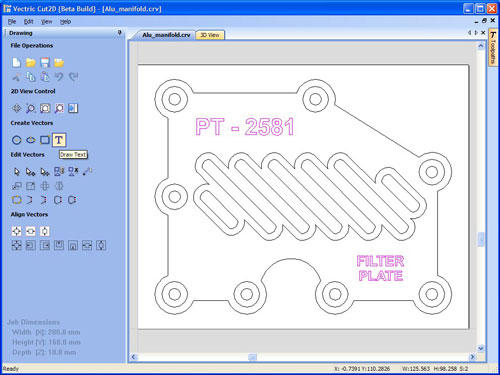

Step 2 - Check the Size, XY Origin, Edit and

Add Text

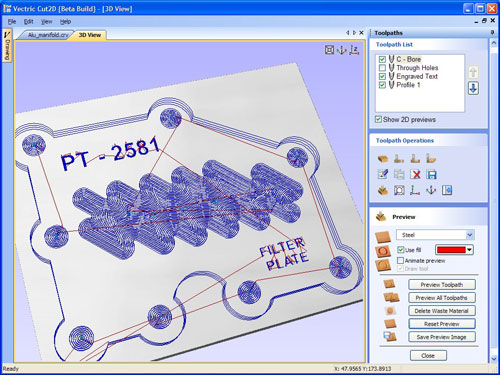

Step 3 - Select the shapes to cut and calculate the toolpaths

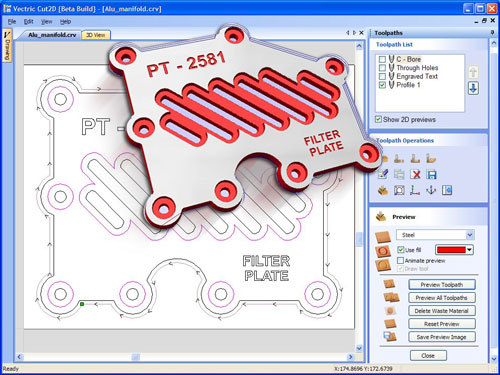

Step 4 -Preview the results and Save the GCode / CNC toolpaths

.

Another alternative is RAMS2D or BobCad

which are other CAD/ CAM programs. It reads in the part

file geometry and performs tool offestting and pocketing functions. The

DigiRout Motion software will interface with just about any CAD/CAM

system you might wnat to use.

| 1. |

Drawing the

Part Geometry to create CAD file usually in DXF format |

| 2. |

Creating the

tool path CAM file in Gcode format |

| 3. |

Running the

toolpath Gcode format to move the Machine |

The

motion controller (pictured below) actually moves the machine in real

time according to the part file generated from the CAM program. It has

advanced contouring features to keep the DigiRout moving along

smoothly. It has DRO readouts to inform you have the current position

and can also simulate the part files before cutting.